Synthetic Gear Bearing Lubricants

Our Synthetic Gear Oils can provide reduced operational temperatures and improved mechanical efficiency over conventional fluids. This means less downtime and lowered energy consumption, ultimately resulting in time and cost-savings for your operation.

Synthetic Lubricants With Excellent Anti-Wear Properties

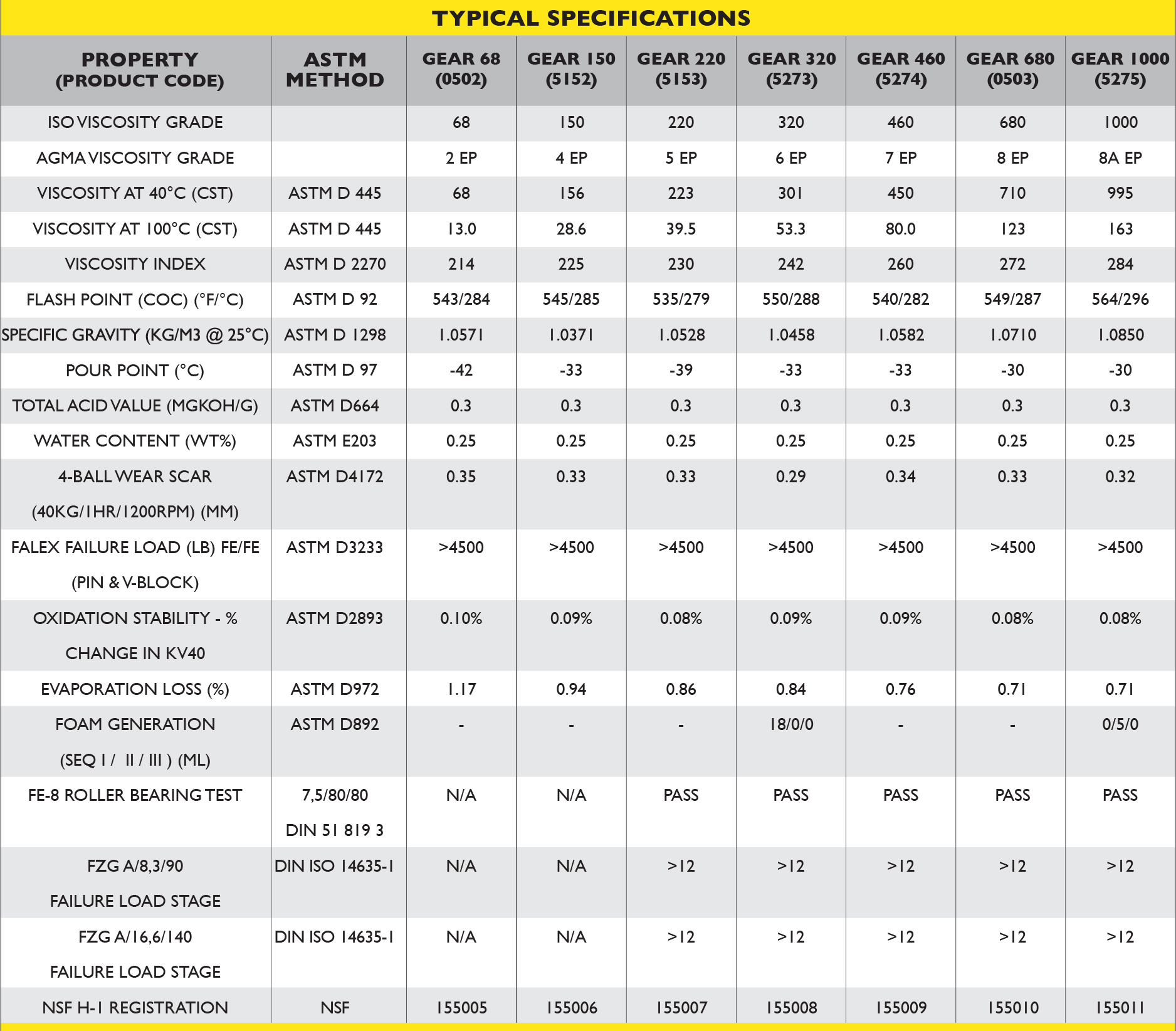

Tulco produces a full line of Lubsoil® Synthetic lubricants designed to provide exceptional lubrication to gears and bearings, from the most basic application to the most extreme conditions. We formulate our synthetic lubricants with the highest-quality synthetic base stocks combined with the latest technological advances in additive systems to provide superior performance in protection of all types of gear and bearing configurations. This includes superior anti-wear, rust and corrosion, and extreme pressure protection properties for all types of high pressure circulating systems, including vain, piston, and gear pumps.

Synthetic Lubricants With High Viscosity Index

Tulco’s line of synthetic lubricants are formulated with either PAO or PAG base stocks with exceptionally high viscosity indexes, which allow the fluid to stay in desired viscosity when subjected to higher temperatures when compared to conventional gear lubricants. Tulco synthetic fluids have superior friction-reducing capabilities, meaning that you can expect less power consumption for your operation. We’ve designed them to provide excellent lubrication for turbines, enclosed industrial gears, and heavily loaded plain and roller bearings that do not require extreme pressure formulated lubricants.

Excellent Thermal And Oxidative Stability

High EP properties allow for protection under harsh stop/start conditions and shock loads. Compatible with both ferrous and nonferrous metal allowing their use in almost all industrial gear and bearing systems, to include spur, helical, and bevel gears. Tulco’s gear bearing synthetic lubricants allow thermally stable operation at temperatures exceeding 200°C, and offer anticipated service lifetimes of all grades in excess of 10,000 hours at 100°C, enabling extended service intervals and, in some instances, a fill-for-life lubricant.

- All types of enclosed gears

- Heavy or Light loaded plain and roller bearings

- Filled for Life Gear Boxes

- Excellent Film Strength

- Outstanding Low and High Temperature Performance

- Multi-Metal Compatible

- Reduced Energy Consumption

- Very Low to No Sludge and Varnish Tendencies

- Extended Drain Intervals compared to conventional fluids

Our synthetic lubricants have solved tough problems for a wide range of customers.