Compressor Synthetic Lubricants

Tulco has designed synthetic compressor lubricants not only for the multiple types of compressors on the market but also for the gasses being compressed. Air, Hydrocarbon gasses, or chemical gasses all effect lubricants in different ways that can be detrimental to the life of the lubricant and the compressor. With that in mind, Lubsoil® has specific products designed to handle all of the different configurations and harsh conditions modern compressors operate in. Multiple synthetic base stocks such as Diester, PAO and PAG offer options that can be tailored for a wide range or pressures, temperatures, and gas streams.

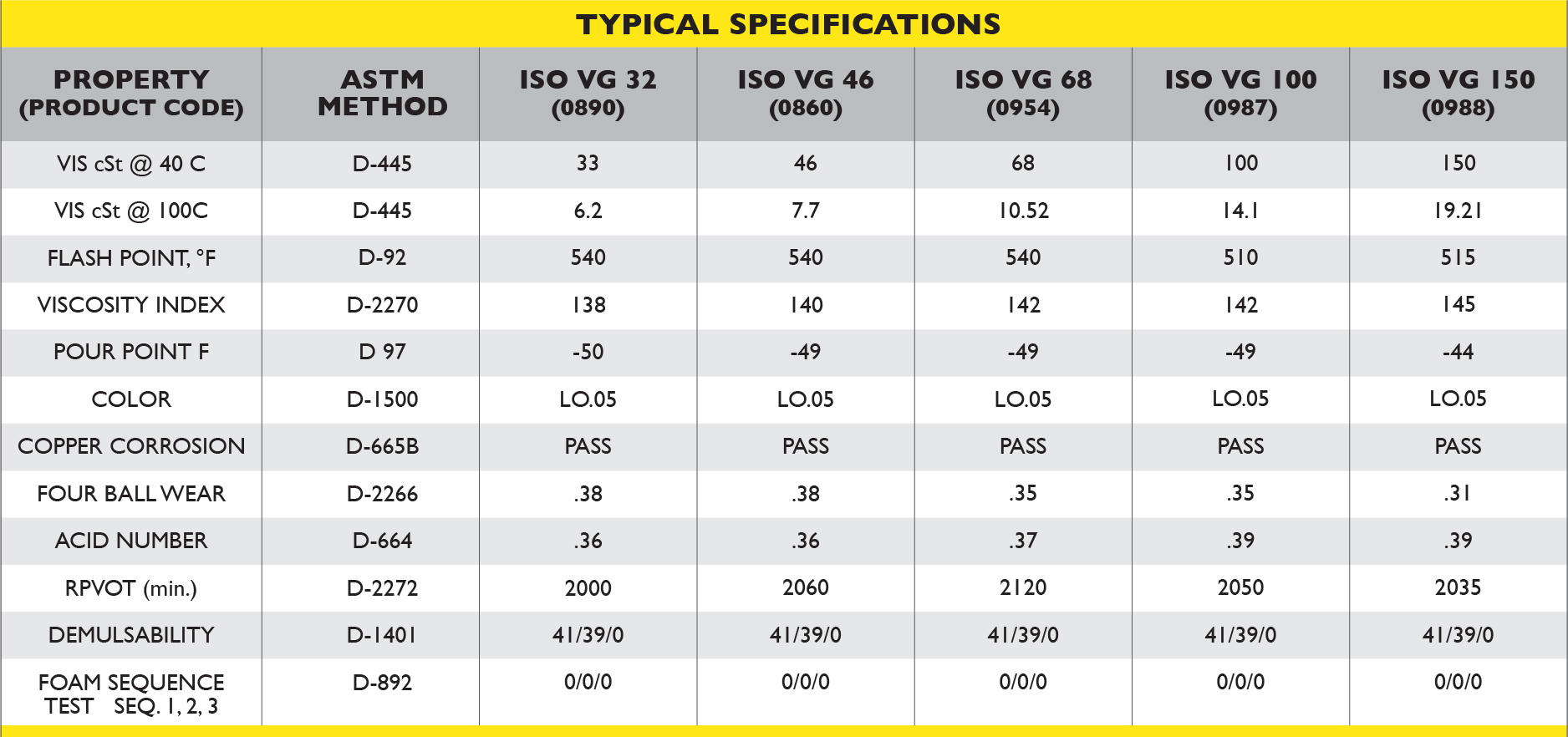

Lubsoil synthetic compressor fluids offer superior performance in the areas of oxidation resistance, deposit control, while also addressing the issues of thermal degradation. Our lubricants can help eliminate the varnish, sludge, and frequent oil changes commonly associated with other lubricants.

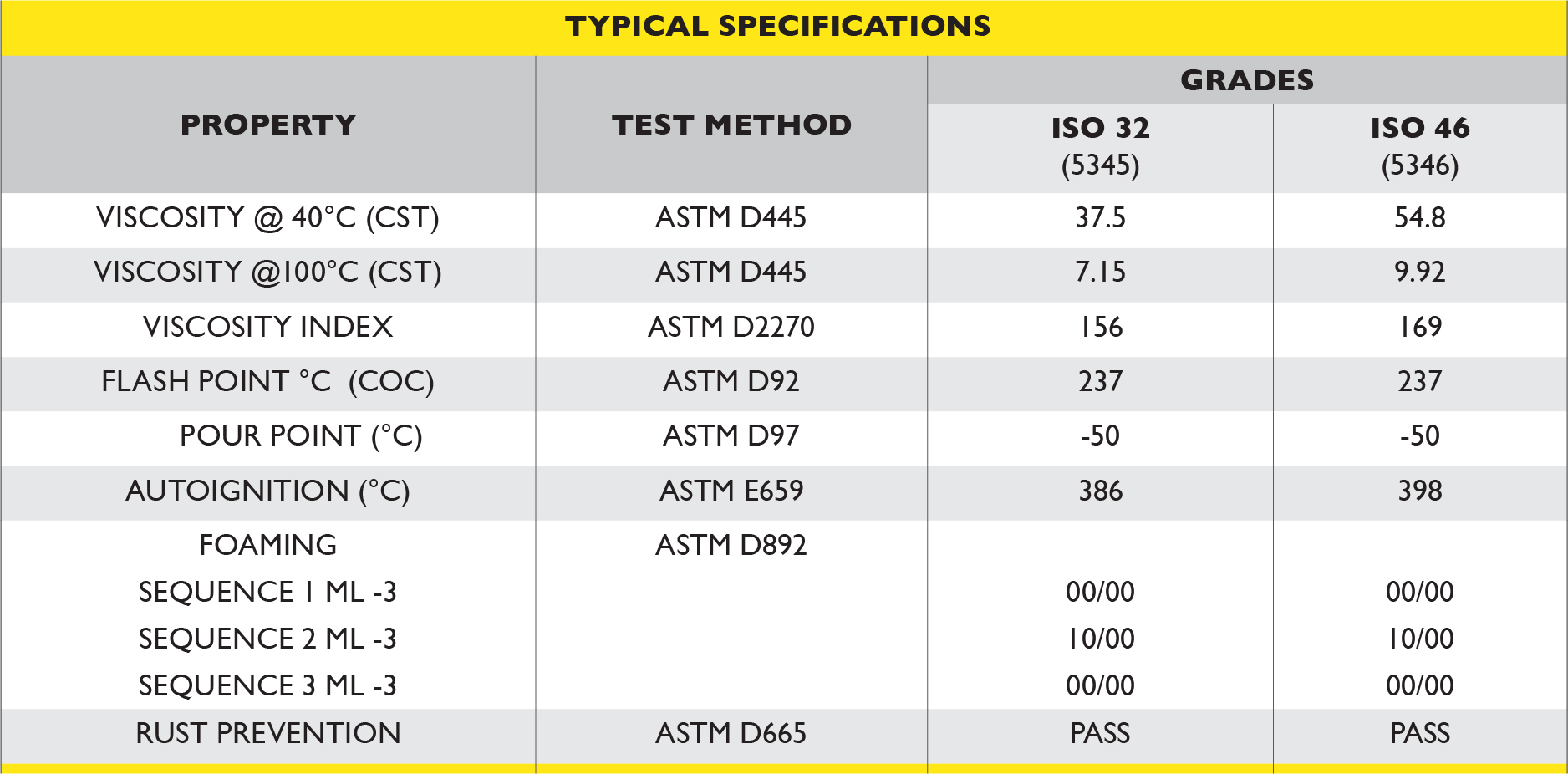

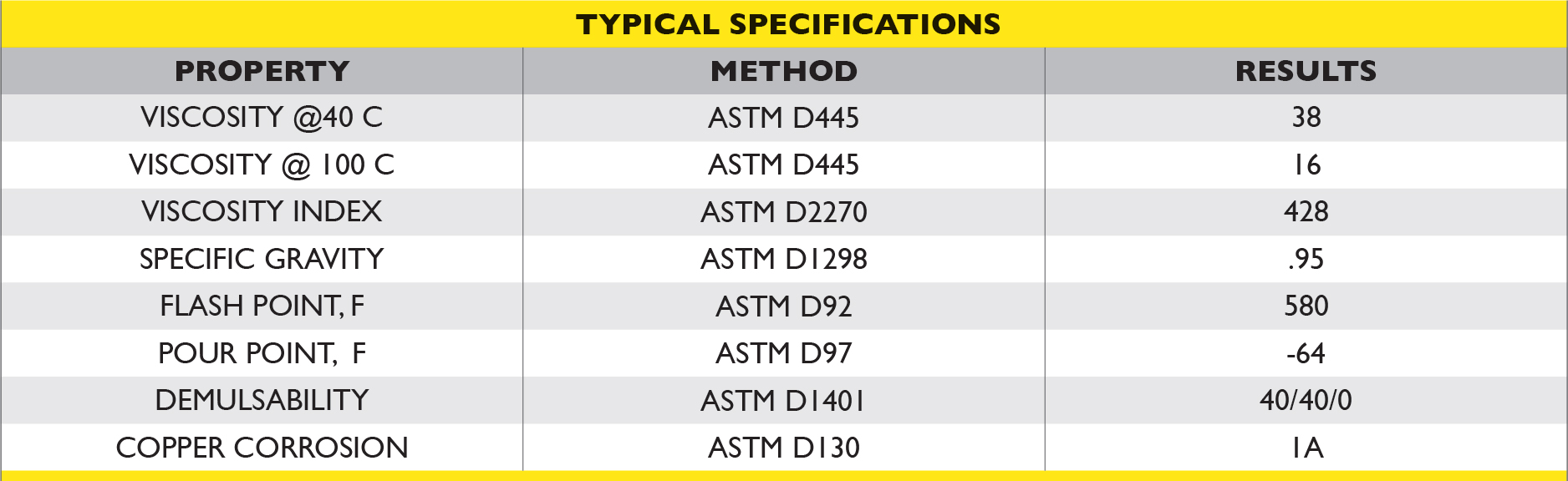

We have specially designed and formulated synthetic lubricants for natural gas compressors. They’ve been formulated to reduce consumption and extend drain intervals in comparison to conventional mineral oil products. The unique additive chemistries provide excellent resistance to carbon and varnish build up, while providing superior lubricity, anti-wear, and oxidative stability. It also inhibits the formation of corrosion from hydrogen sulphide gases.

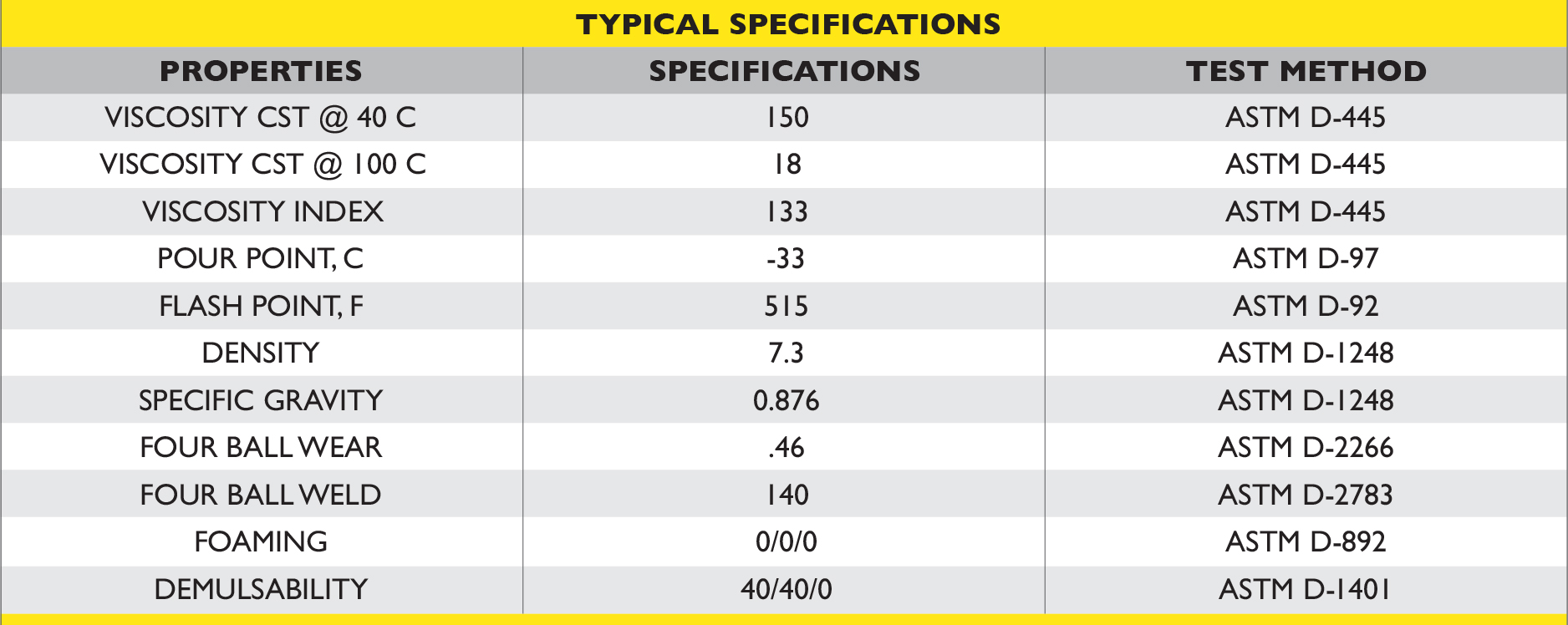

Some Lubsoil synthetic compressor lubricants are particularly suitable for use with heavy gases. Our high performance synthetic lubricants are specifically designed to minimize viscosity dilution and extend equipment life. High resistance to gas dilution of the lubricant ensures proper lubricant viscosity is maintained, thereby ensuring adequate oil film thickness and efficient compressor lubrication. And unlike other oils, Tulco’s line of compressor lubricants are not easily absorbed into the gas stream and therefore lubricant dilution is significantly minimized.

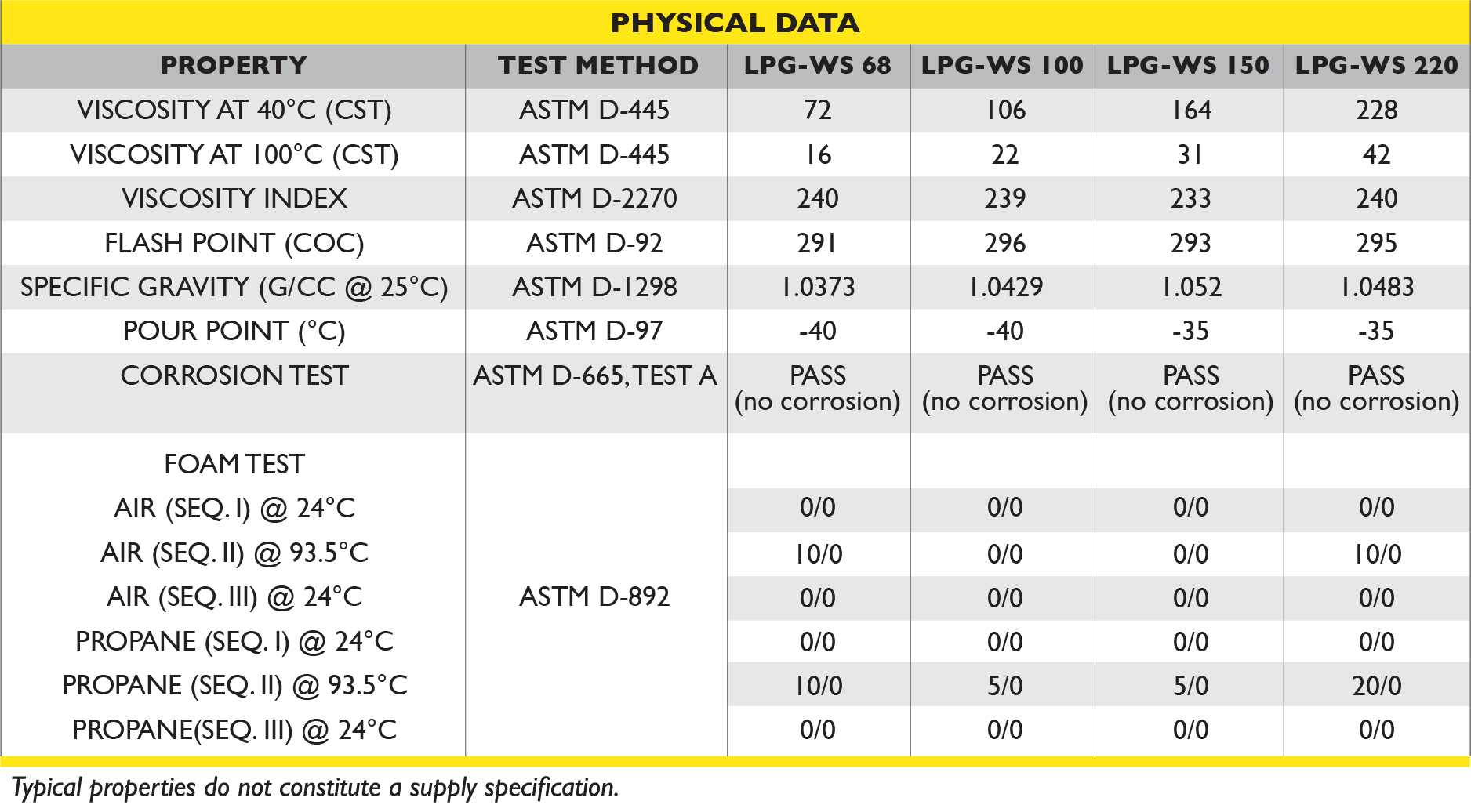

Our lubricants demonstrate superior resistance to wash-out by condensed hydrocarbon liquids compared to other compressor lubricants, as well as the minimization of oil consumption by carryover into the gas stream. They are a precise synthesis of premium PAG base oil and sophisticated additives to ensure long service life, excellent wear protection, corrosion resistance (particularly in consideration of hydrogen sulfide gas content), and high thermal and oxidation resistance.

Lubsoil PAG compressor lubricants are designed for enclosed pattern hydrocarbon and chemical gas compressors where the crankcase and bearings operate in a gas-filled environment. Our lubricants are high performance, fully synthetic, polyalkylene-glycol-based lubricants designed to minimize viscosity dilution and extend equipment life. Our synthetic compressor fluids are designed with state-of-the-art additive technology to provide extremely long run times in compressors.

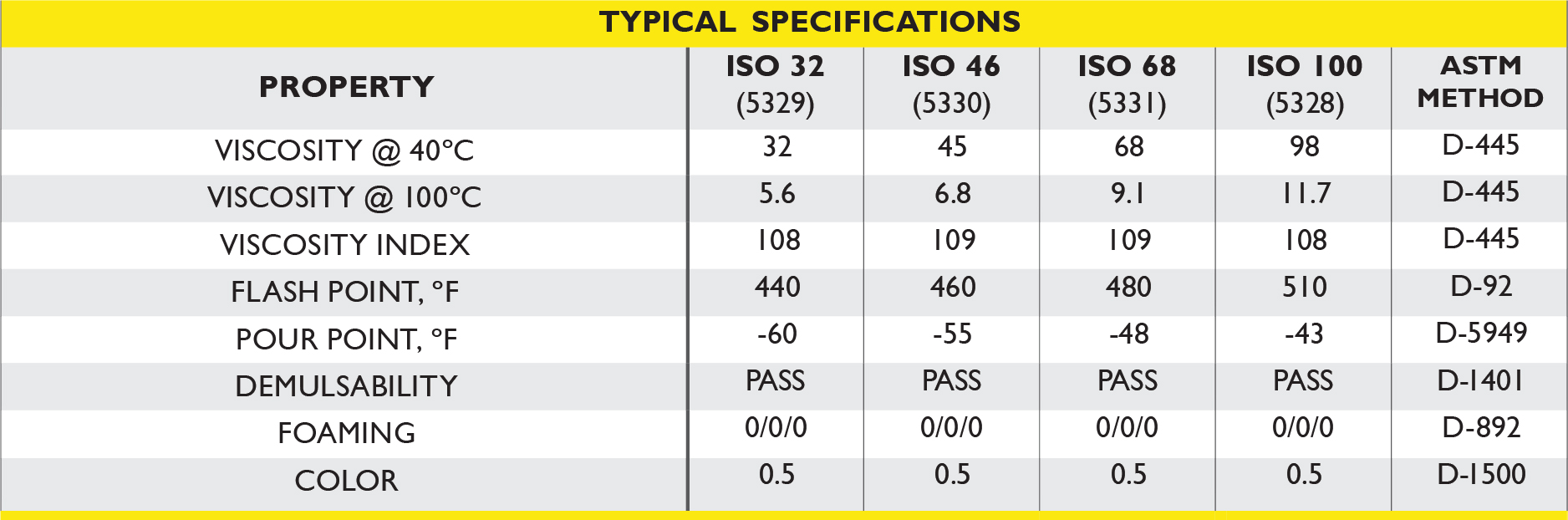

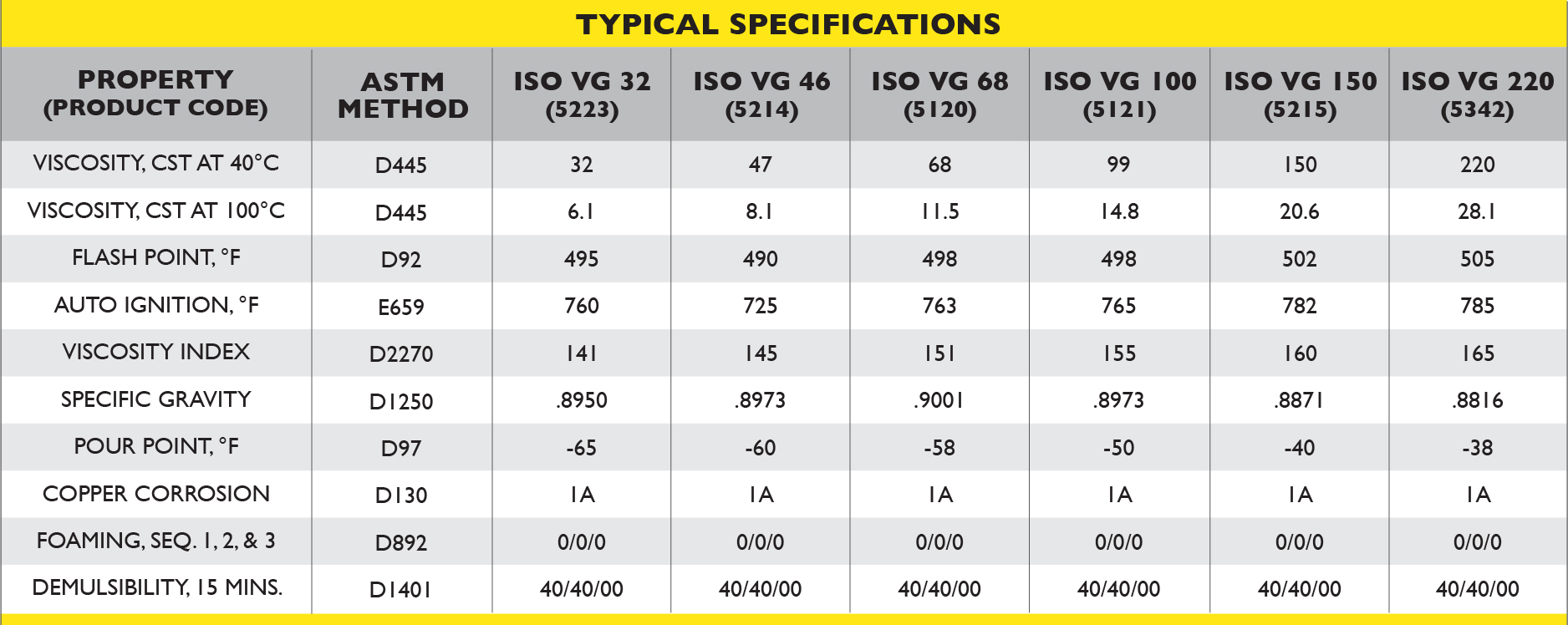

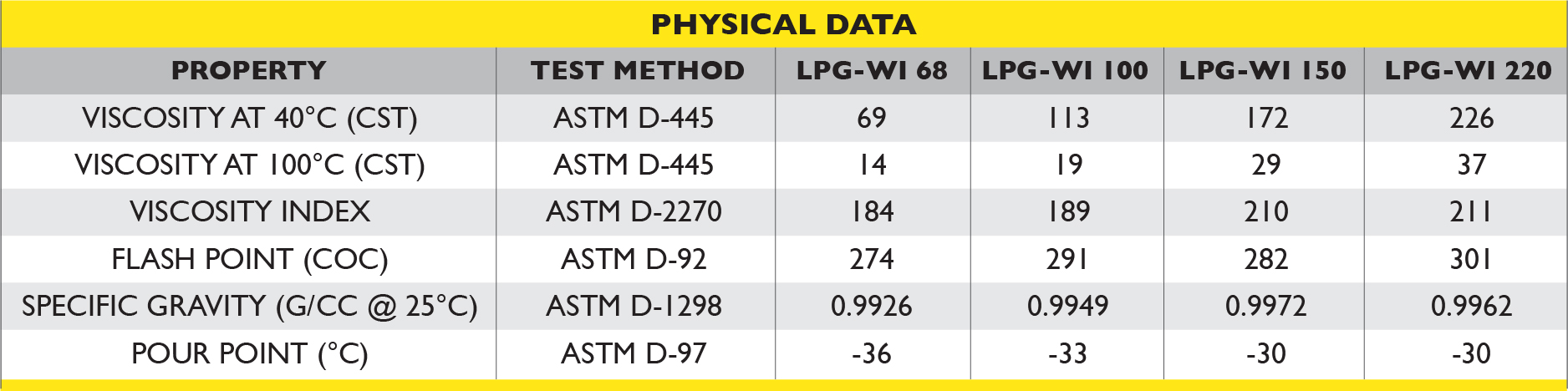

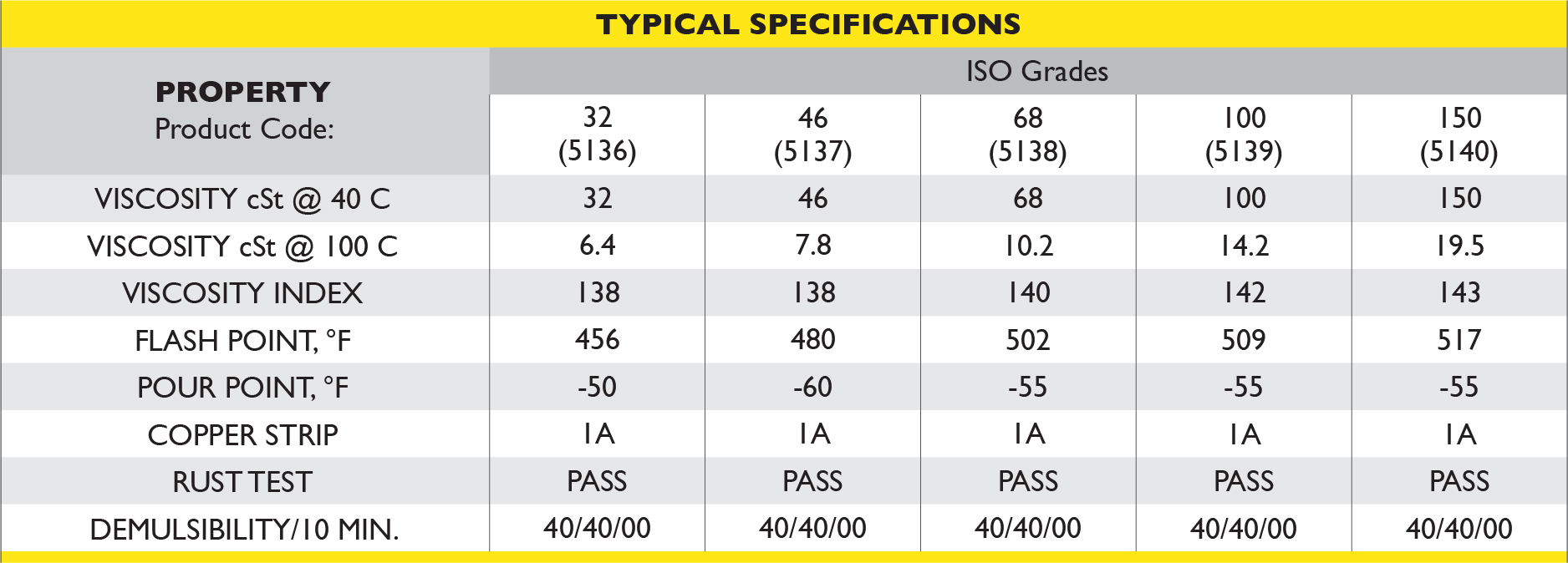

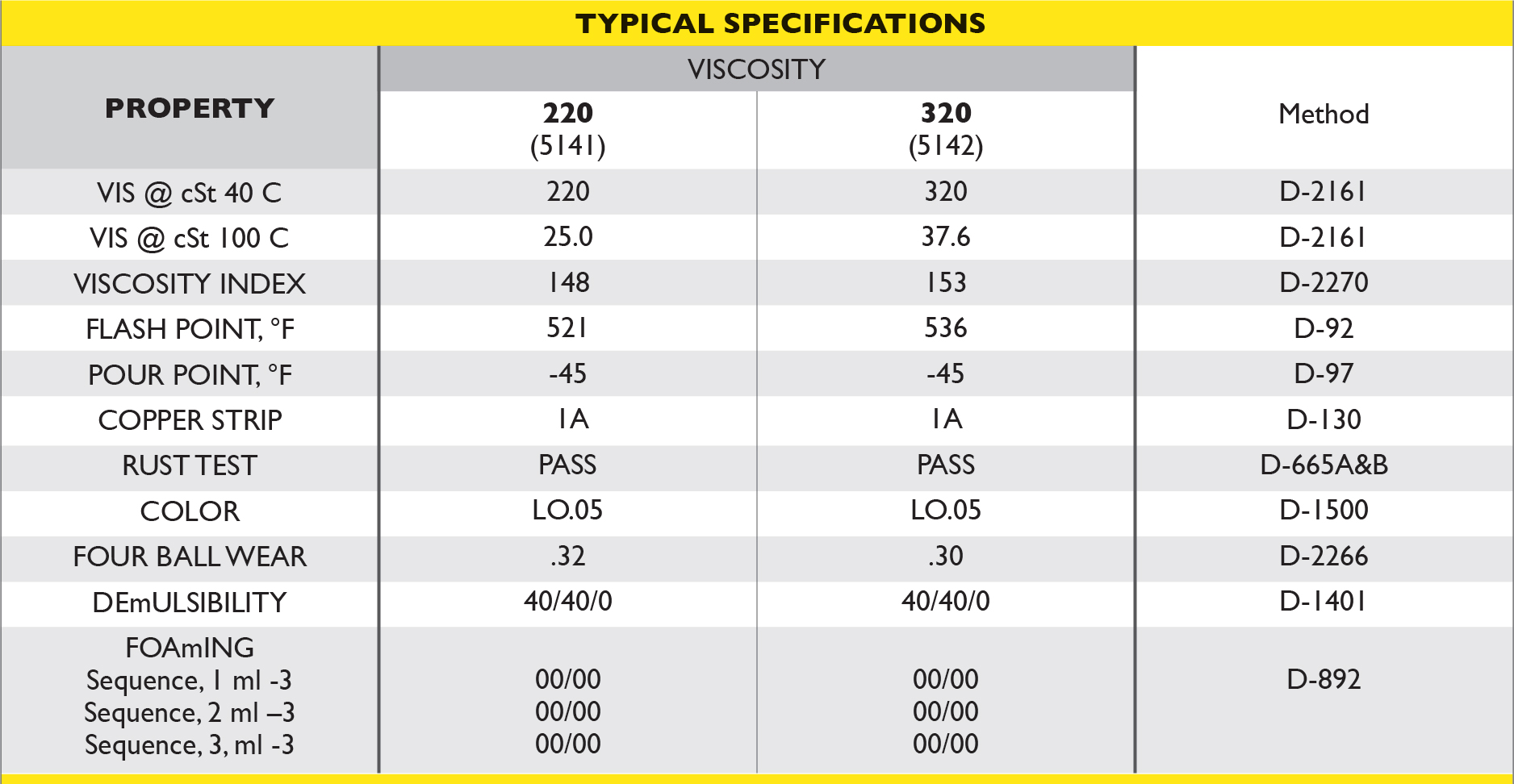

Tulco has uniquely designed and formulated our synthetic compressor lubricants to contain the highest quality synthetic-base stocks and the latest technology of advanced additive systems to provide maximum protection in rotary screw, centrifugal, and reciprocating compressors. This state-of-the-art technology offers huge benefits in comparison to petroleum or semi-synthetic based fluids that are commonly utilized in the industry. Our synthetic compressor lubricants possess high viscosity indexes to offer protection in elevated temperatures, have very low sludge and varnish-forming tendencies, and—with their low pour points—are able to operate in low temperature operations, making them a versatile, efficient solution for a wide variety of operations.

- Rotary Screw Compressors

- Reciprocating Compressors

- Rotary Vane Compressors

- Blowers

- Vacuum Pumps

- Excellent Oxidation and Thermal Stability

- Very Low to No Sludge and Varnish Tendencies

- Extended Service Life

- Lower Maintenance Costs

- Reduced Gas Solubility

- Reduced carryover/consumption

Our synthetic lubricants have solved tough problems for a wide range of customers.