Gun Drilling Grinding & Honing Industry Applications

Deep-hole drilling is typically the process of machining holes greater than 10:1 depth to diameter ratio. Deep-hole drilling involves the use of gundrilling, BTA drilling, and ejector drilling, along with additional processes designed specifically to meet very narrow tolerance limits and allow a high degree of precision and accuracy.

Gundrills are straight-fluted drills which allow cutting fluid to be injected through the drill’s hollow body to the cutting edge. With BTA drilling, the cutting head utilizes a tube to get to depth, with the metalworking fluid pumped down the outside of the tube and cutting head, with the chips carried out through the center of the tube.

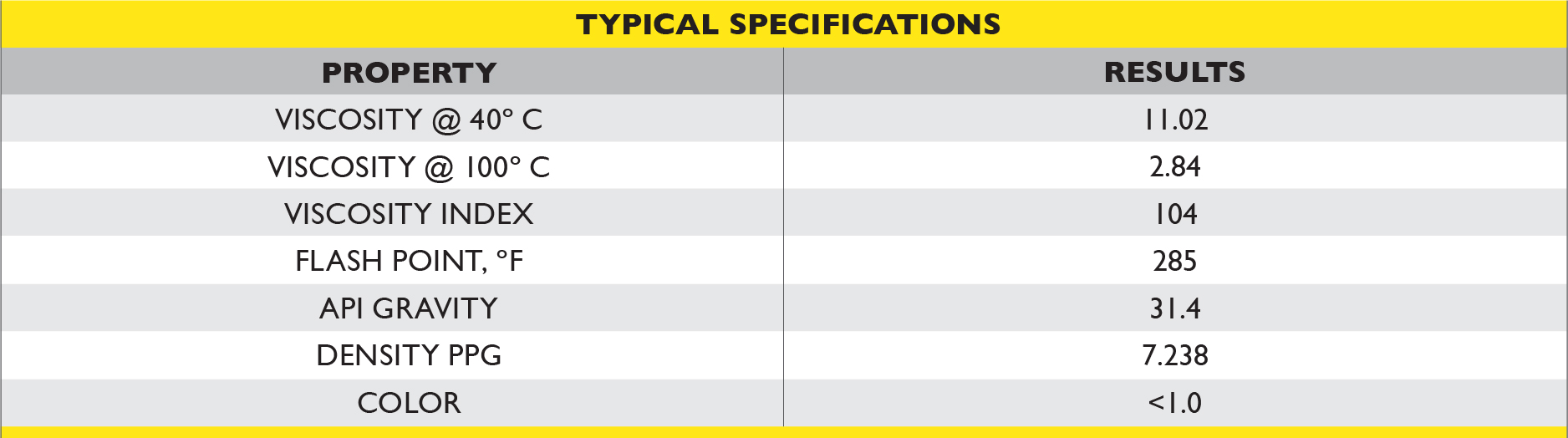

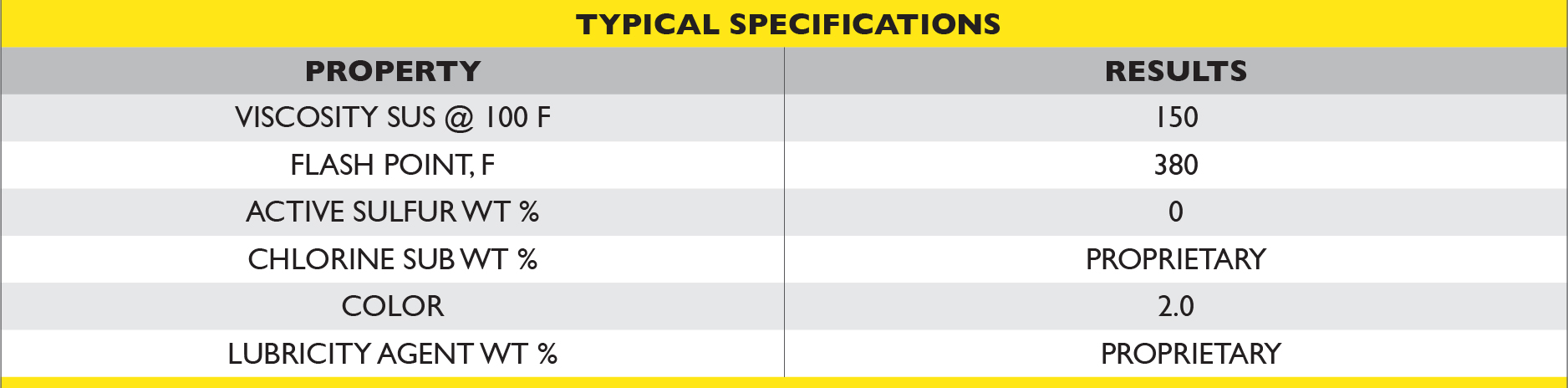

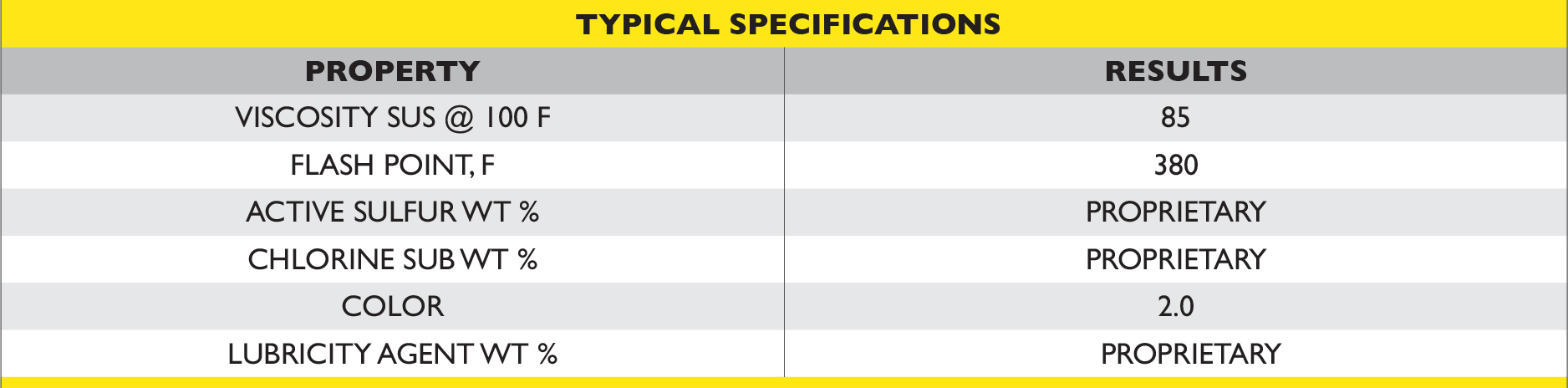

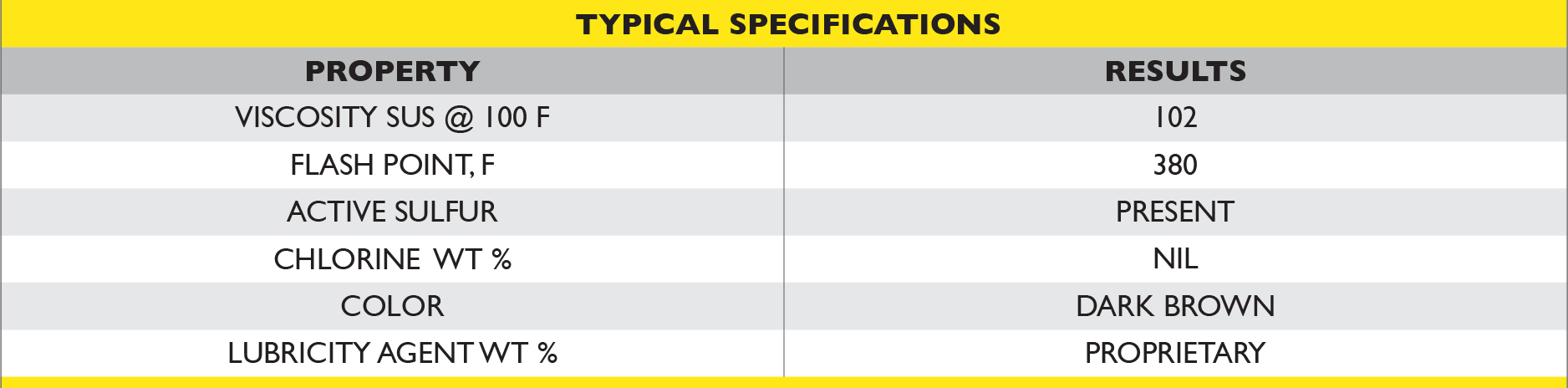

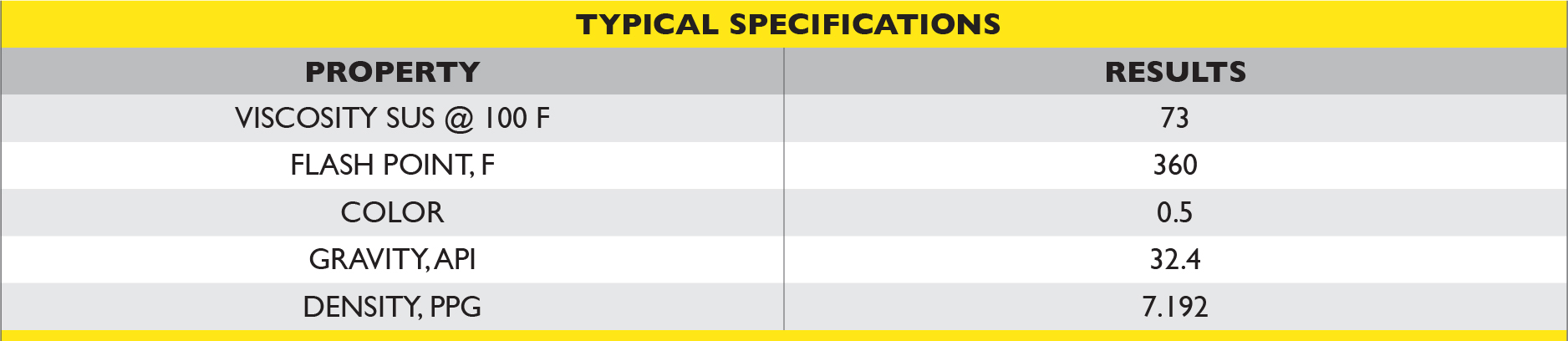

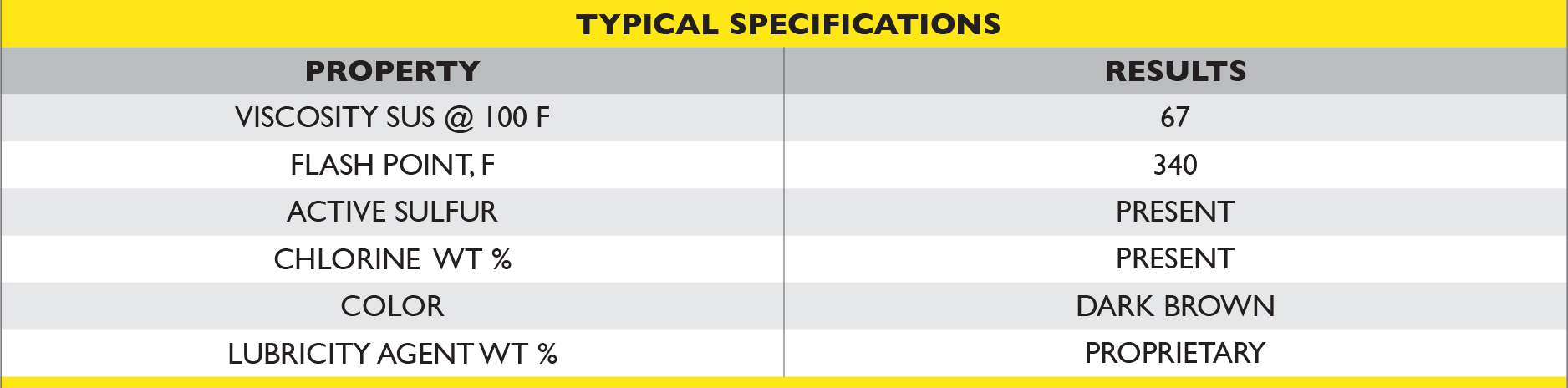

Ejector drilling is a twin-tube system with the metal working fluid being supplied between the inner and the outer tube. Tulco understands the complications involved with deep-oil drilling and has designed multiple gundrill oils to meet the lubrication needs for this complicated operation.

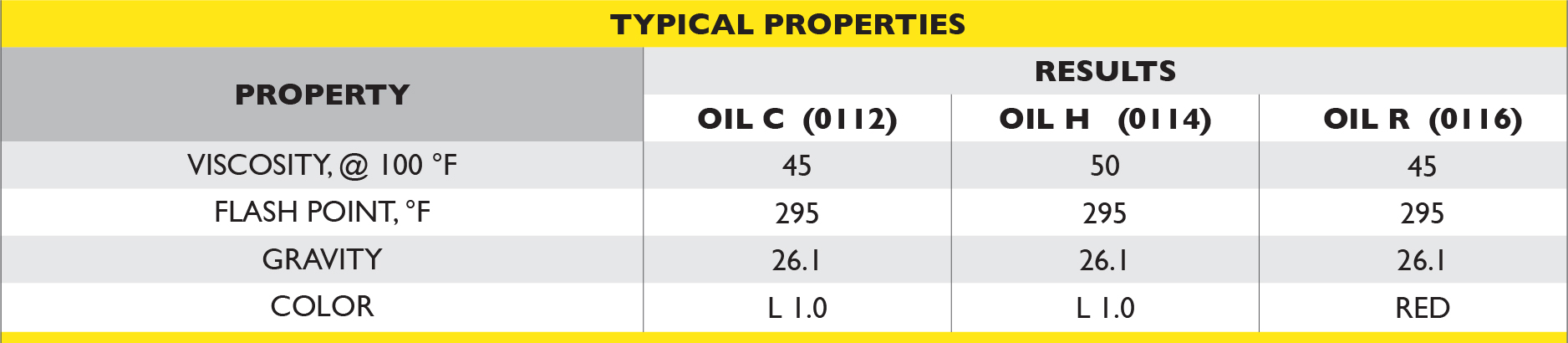

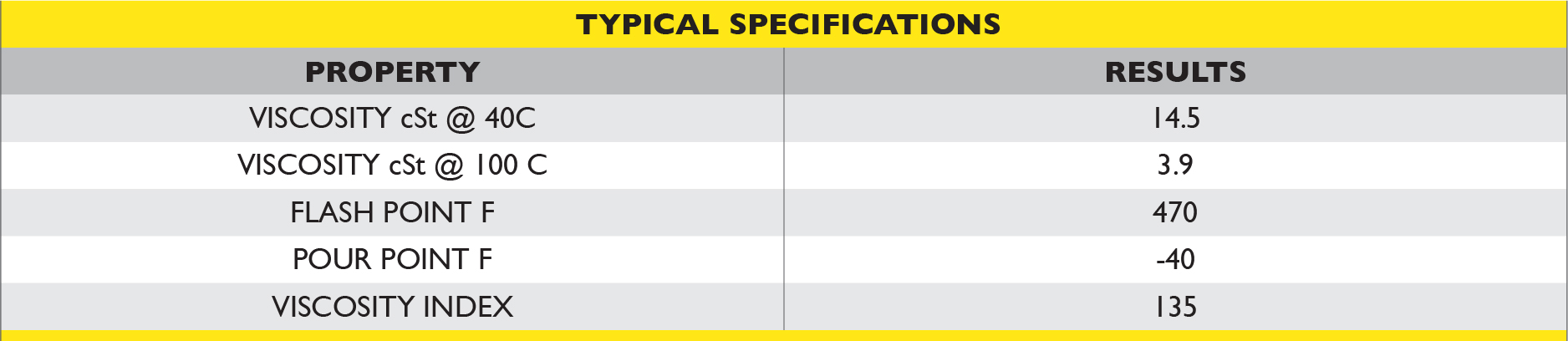

Grinding typically refers to the removal of large amounts of material to achieve a certain shape, while honing is used to achieve a precision surface with a specific finish. Both operations utilize a stone made of abrasive material. One of our Tulco experts can help you select proper grinding and honing oils in line with the type of operation and the type of stone being utilized.

- Deep Hole Drilling

- Grinding

- Honing

Extended tool/stone life

Separates from chips/swarf easily

Low and high pressure capable

Produces excellent surface finishes

Our Lubsoil® products have been a solution for a wide range of metalworking applications.