Metalworking Quench Oils Industry Applications

Quench oils have two primary functions:

- Facilitating the hardening of steel and steel alloys by controlling heat transfer during the quenching process.

- Enhancing the wetting of steel to minimize the formation of undesirable thermal gradients, which may lead to distortion and cracking.

Heat transfer rates increase with lower viscosities and decrease with increasing viscosity. When using quench oils to cool metal, there are three stages:

- The vapor phase is when the hot metal is first introduced into the quench oil.

- After the cooling has begun, the boiling phase starts.

- Finally, once the temperature is lowered below the quench oil’s boiling point, the convection-cooling stage starts.

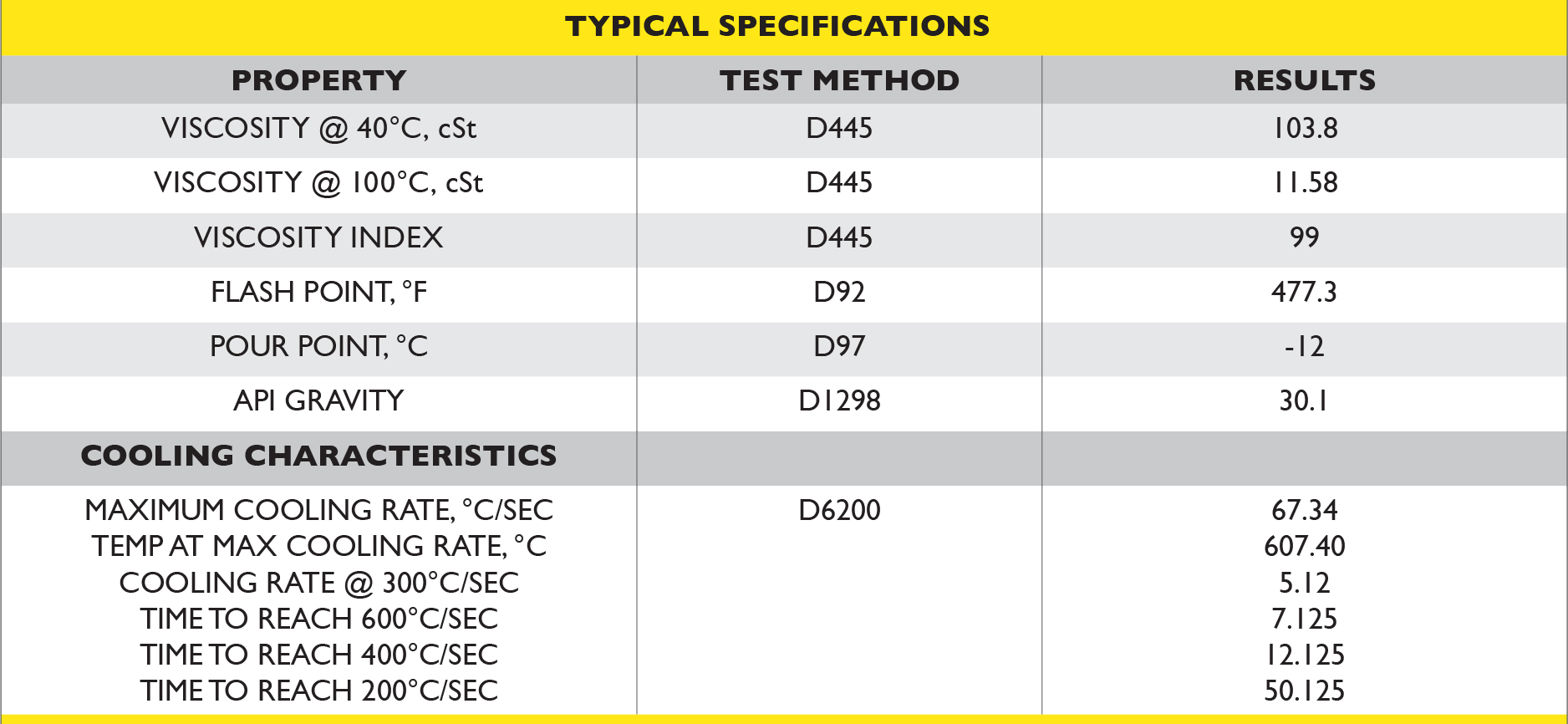

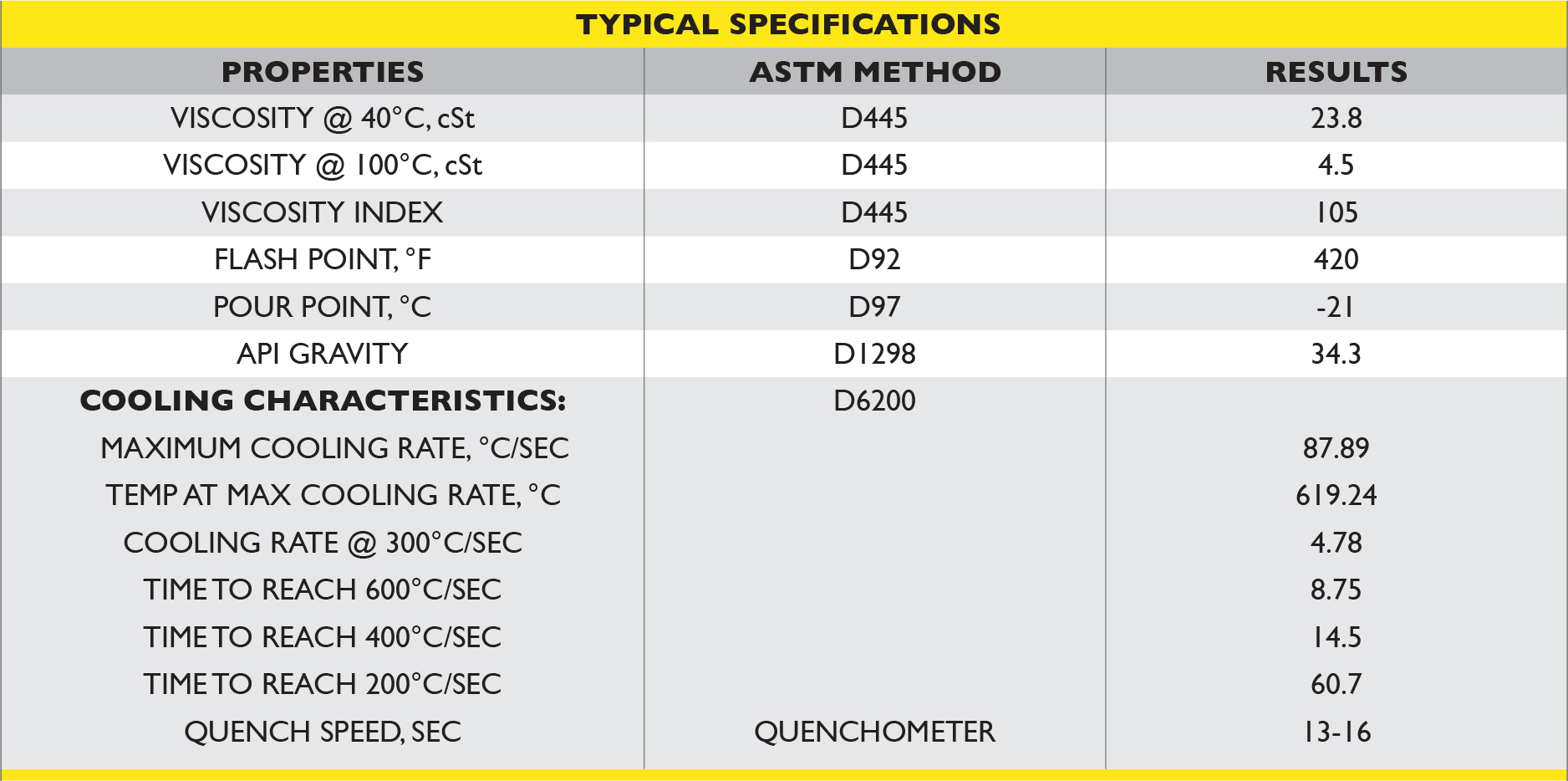

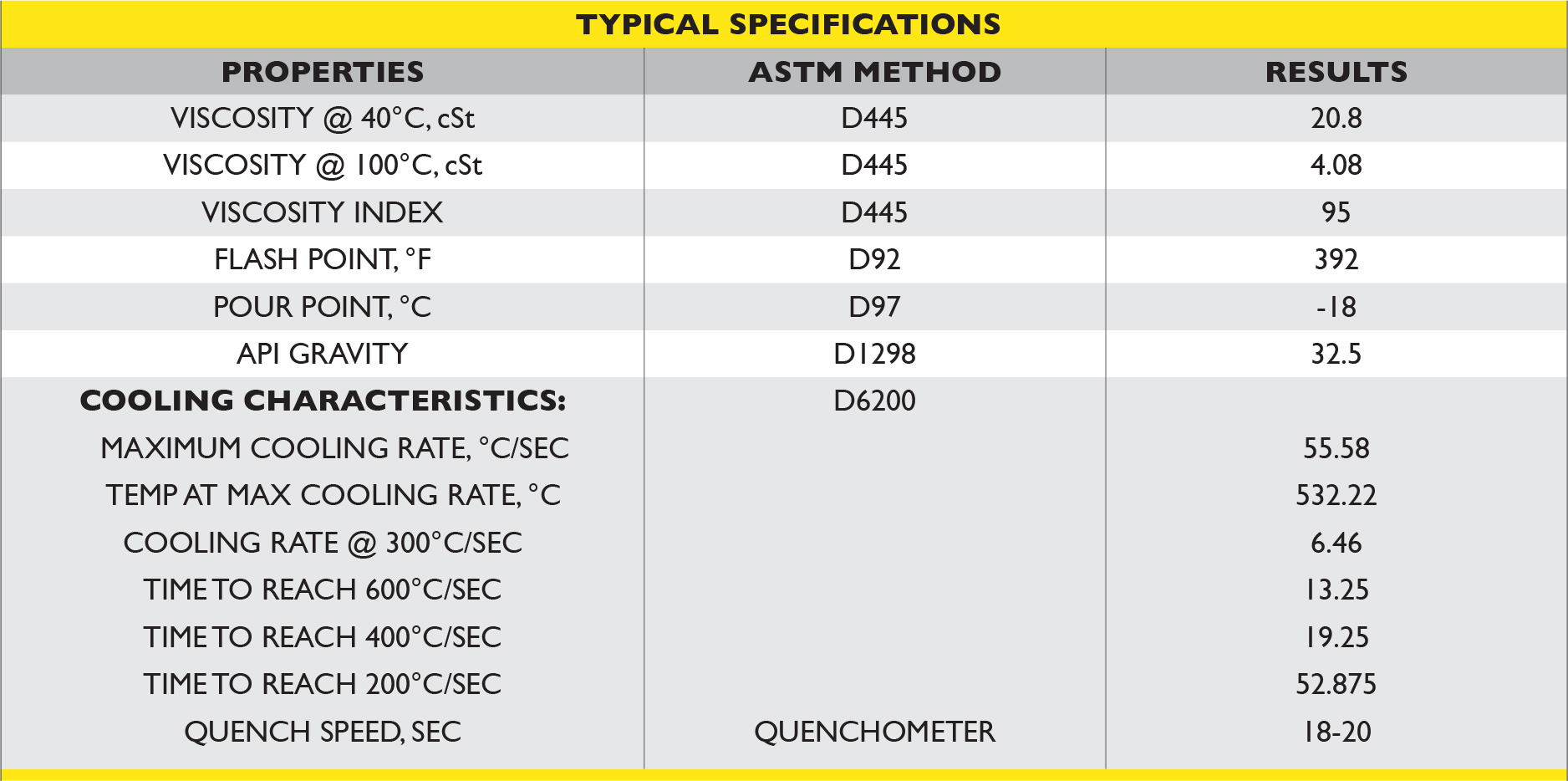

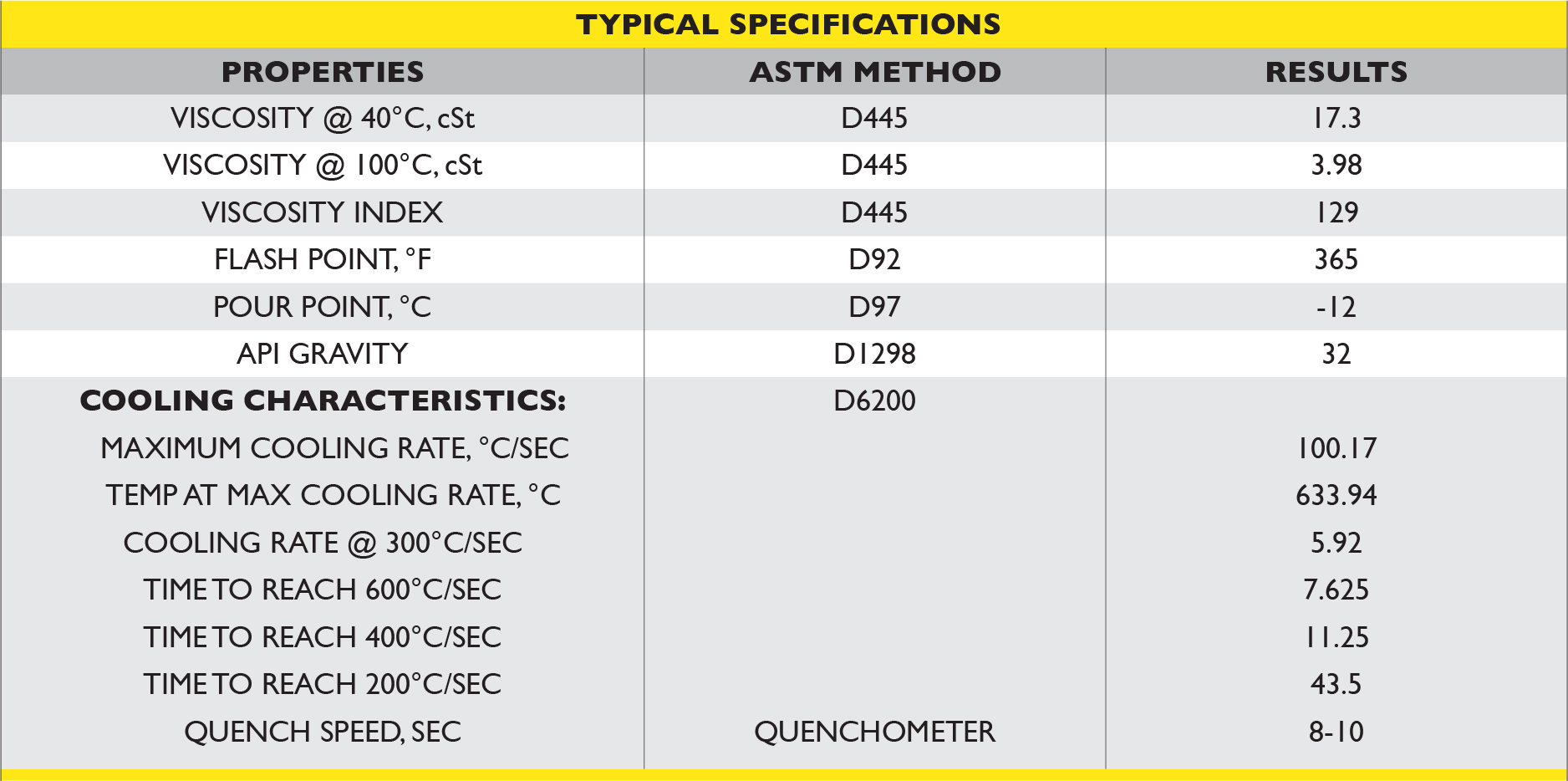

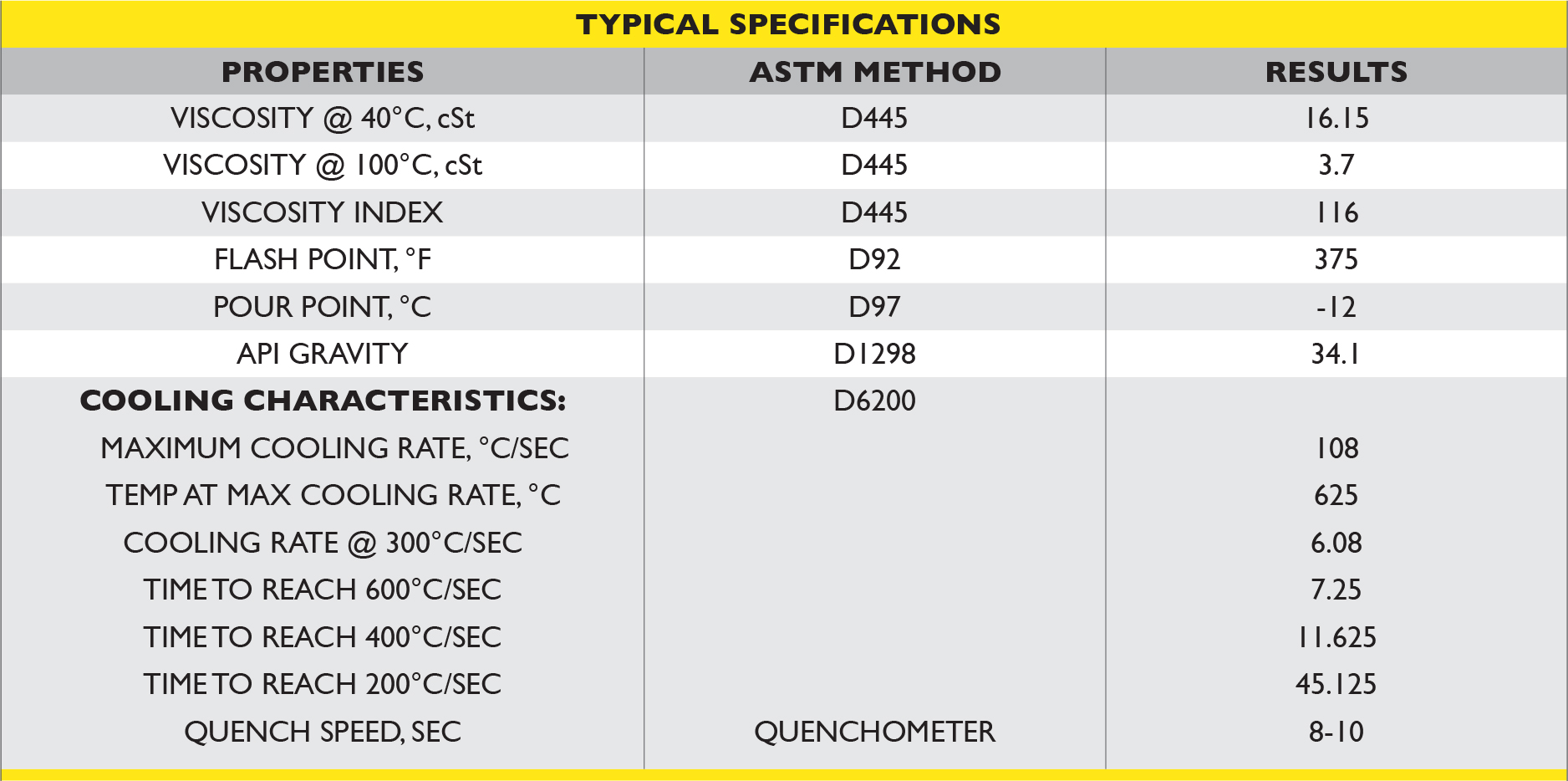

Tulco offers multiple quench oils designed with different viscosities and quenching speeds to meet different hardness requirements. Rest assured, our quench oils have exceptional thermal stability, are resistant to oxidation, and are effective on tightly packed parts.

-

Quenching of steel and steel alloys

- Exceptional Thermal Stability

- Very Resistant to Oxidation

- Reduces Drag Out

- Effective on tightly packed parts

Need more information or want to place an order? One of our lubricant specialists can help you out!

Our Lubsoil® products have been a solution for a wide range of metalworking applications.